Consequently, the exploration of rubber and its marriage with textiles not only enriches our comprehension of fabric science but in addition encourages creative imagination and innovation in potential models and purposes.

The rubber covered yarn market has experienced substantial growth in recent years, driven by raising demand from customers from numerous end-use sectors and ongoing technological enhancements.

We have been related to Tradeindia considering the fact that 2017. It really is a very good on-line B2B portal to market SME's organization online and also offline.

Mechanical energy is frequently evaluated by means of tension and pressure screening, furnishing insights on how the yarn performs beneath numerous masses. The elastic Qualities of rubber deliver impressive flexibility, allowing for the yarn to stretch though retaining its unique condition.

Moreover, the durability of rubber material is evident in its resistance to abrasions and many chemical substances. These Homes are Particularly effective in workplaces exactly where workers might come into connection with severe elements or get the job done in soaked environments. Therefore, rubber cloth fulfills both of those basic safety and practicality in its apps.

The combination of rubber covered yarn with intelligent textile systems has opened up new prospects in the realm of wearable products and interactive fabrics.

Rubber covered yarn serves numerous capabilities, but its Principal purpose is to deliver toughness and elasticity to textiles. It really is greatly used in specialised purposes, including the production of elastic elements, bands, and numerous varieties of strengthened fabrics.

These traits highlight the dynamic mother nature in the rubber covered yarn business and underscore the significance of ongoing innovation and adaptation to fulfill evolving marketplace needs.

Additionally, rubber covered yarn exhibits outstanding resistance to environmental stressors, which include humidity and chemical publicity. This kind of resistance makes it a appealing applicant for products and solutions in industries for example automotive, where resistance to drinking water and wear is paramount.

Form Retention: Spandex-coated heel counters can keep the shape in the shoe upper, preventing deformation or sagging, thus assisting to maintain the looks and functionality in the footwear.

Dip Coating: The substrate is immersed in the liquid rubber compound and then withdrawn at a managed level. This method is usually employed for gloves, small elements, plus some textiles.

Its capability to satisfy varied demands across a number of industries highlights its relevance being an modern and adaptable substance in now’s world.

a) Waste Reduction: Rubber yarn brands typically make use of recycled rubber elements, which includes post-client waste like discarded tires or rubber scraps from industrial procedures. By repurposing these products, rubber yarn makers contribute to waste reduction and the circular economy.

From healthcare equipment to check here sports add-ons and defend protectors, this adaptable material has become an integral element in making certain safety and luxury throughout many industries.

Ariana Richards Then & Now!

Ariana Richards Then & Now! Matilda Ledger Then & Now!

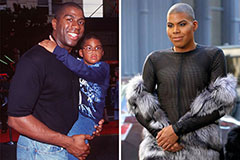

Matilda Ledger Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Atticus Shaffer Then & Now!

Atticus Shaffer Then & Now!